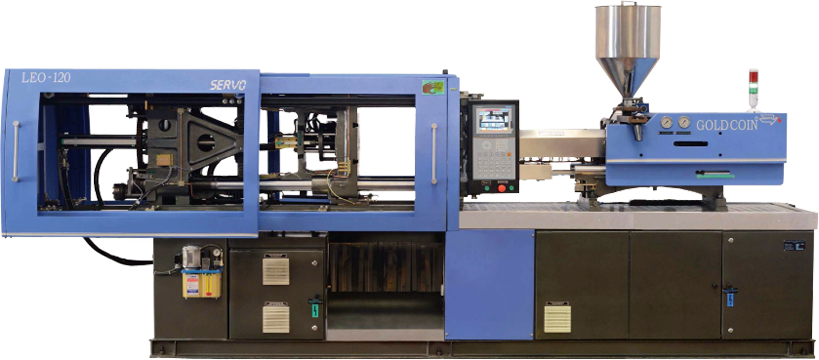

Single Color Thermoplastic Injection Molding

LEO Series

Clamp

- Robust Integrated Casted Five Point Twin Toggle Clamping System

- T-Slot for Easy Mould Change-Over

- Box Type Moving Platen

- Automatic Mold Height and Tonnage Built-Up System

- Five Stage Closing / Four Stage Opening Speed Setting

- Accurate and Sensitive Low Pressure Mold Safety

- Linear Transducer for Accurate Clamp Position

- Centralized Automatic Lubricating System (Grease Based)

- Core Pulling System (Single Cylinder)

- Core Pulling System (Provision For Second Cylinder)

- Hydro Electrical Guard Safety

- Product Drop Sensor (Single Cavity)

Injection

- Multi Stage Variable Injection Pressure & Speed Profile

- Two Stage Variable Pressure / Speed Hold On Position

- Injection Profile for Monitoring Injection Function

- Radial Piston Hydro Motor

- Three Stage Variable Pressure / Speed for Refilling

- Digital RPM Indicator System

- Linear Scale for Accurate Injection Position Control

- Suck Back (Before/After Refilling)

- Semi-Auto Purging Program

- Intrusion Molding Program / Flow Moulding

- Sprue Break with Timer

- Lubricating System for Injection (Grease Based - Manual)

- Sealed Nozzle Tip Heater

- Purging Cover Safety

- Back Pressure Control (Manual)

Ejector

- Knock Out Bar

- Multi-Point Programmable Hydraulic Ejector (Two Stage Position)

- Pulse Setting Ejector Operation

- Ejector Retract Position Sensing Safety

- Air Ejector System For The Both Halves

Temperature

- Auto Tuning PID Temperature Control System

- Temperature Monitor Graph Actual V/s Set Value

- Weekly Program for Temperature Auto Power On

- SSR Based Heating Control

Programmable Logic Controller

- Color Monitor Display

- PLC Program Ladder Basis

- Dual High Speed 32 Bit CPU

- Password With Multi Level Setting

- All Functions Real Time Display

- Unscrewing Program

Hydraulic

- Energy Efficient Servo Motor System.

- Single Module Pump Motor Mounting Base for Easy Maintenance

- Alarm for High Oil Temperature

- Appropriate Placement / Indication for Hydraulic Valves - Easy Approach

- Return Line Oil Filter

Others

- Motor Running Hour Display

- Total Production Count

- Batch Count

- Actual Process Monitoring Data Display For Last 100 Cycles

- Alarm Display For Last 120 Events

- Mold Memory Storage Up To 100 Nos.

- Display for Process Data for Last 120 Changes

- Flexibility Of Off Loading for Program through USB Port

- Monthly Production Count / Chart Hourly Basis

- Easy Diagnosis For Fault Finding Through In Put / Out Put Display

- Push Button Selection For Semi-Cycle Operation

- Electrical Socket In-Built (Single Phase / Three Phase)

- Single Phase Preventer For PLC

- Audio-Visual Alarm

- Robot Interface Connectivity

- Provision For Continuous Oil Filtration Unit.

Standard Tools

- Tool Kit

- Leveling Pad - One Set

- Mold Clamp - One Set

- Lubrication Grease - Five Kg

- Hopper Magnet - One No.

- High Speed Ethernet Communication Between HMI And Remote I/O Module.

- Bi-Metallic Screw Barrel.

- Energy Efficient Variable Displacement Pump.

- Water Battery With Temperature Indicator.

- Dynamic Barrier Screw.

- Back Pressure Control Through PLC.

- Ejector On Fly.

- Energy Meter.

- Tonnage Indicator on PLC Screen.

- Insulation Plus Heater.

- Feed Throat Temperature Indicator.

- PLC Screen - 10" Colour Monitor.

| Description | Unit | LEO 60 | LEO 80 | LEO 120 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Item | A | B | C | A | B | C | A | B | C | |

| Injection Unit | ||||||||||

| Screw diameter | mm | 26 | 30 | 34 | 35 | 37 | 40 | 37 | 40 | 43 |

| Screw L/D ratio | L/D | 24 | 21 | 19 | 20.6 | 19.5 | 18 | 21.1 | 19.6 | 18.2 |

| Shot volume (Theoretical) | cm3 | 66 | 88 | 113 | 123 | 137 | 160 | 172 | 201 | 232 |

| Shot weight (P.S. Based) | gms. | 60 | 80 | 103 | 110 | 123 | 145 | 154 | 181 | 209 |

| Injection pressure | BAR | 2450 | 1840 | 1430 | 1930 | 1730 | 1480 | 1960 | 1680 | 1450 |

| Injection Speed | mm/s | 105 | 85 | 106 | ||||||

| Injection Stroke | MM | 125 | 125 | 165 | ||||||

| Plasticising Cap (ps) @ Max. Speed | GM/SEC | 8 | 9.3 | 12 | 14 | 14 | 19.2 | 15.7 | 15 | 23.6 |

| Screw speed | rpm | 0~220 | 0~220 | 0~230 | ||||||

| Clamping Unit | ||||||||||

| Clamping force | TONNES | 60 | 80 | 120 | ||||||

| Toggle Strock | mm | 265 | 320 | 365 | ||||||

| Space between tie bars | mm | 310 x 310 | 365 x 365 | 410 x 410 | ||||||

| Max. Mould Height | mm | 320 | 380 | 450 | ||||||

| Min. Mould Height | mm | 120 | 150 | 160 | ||||||

| Ejector Stroke | mm | 70 | 100 | 130 | ||||||

| Ejector Force | TONNES | 2.2 | 2.75 | 3.96 | ||||||

| Ejector Number | n | 4 | 5 | 5 | ||||||

| Others | ||||||||||

| Max. Pump Pressure | BAR | 150 | 150 | 150 | ||||||

| Pump Motor Power | KW | 7.5 | 11 | 11 | ||||||

| Heater Power | KW | 5.2 | 5.8 | 9.1 | ||||||

| Machine Dimensions (L x W x H) | m | 3.78 x 1.02 x 1.81 | 3.92 x 1.08 x 2.04 | 4.39 x 1.12 x 2.08 | ||||||

| Oil Tank Capacity | Liter | 130 | 185 | 230 | ||||||

| Machine Weight | Ton | 4 | 4.5 | 5 | ||||||

| Description | Unit | LEO 140 | LEO 180 | LEO 240 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Item | A | B | C | A | B | C | A | B | C | |

| Injection Unit | ||||||||||

| Screw diameter | mm | 40 | 45 | 48 | 45 | 50 | 55 | 50 | 55 | 60 |

| Screw L/D ratio | L/D | 22.5 | 20 | 18.8 | 22.2 | 20 | 18.2 | 22 | 20 | 18.8 |

| Shot volume (Theoretical) | cm3 | 270 | 342 | 389 | 334 | 412 | 499 | 490 | 593 | 707 |

| Shot weight (P.S. Based) | gms. | 243 | 308 | 350 | 301 | 371 | 449 | 442 | 534 | 636 |

| Injection pressure | BAR | 2010 | 1590 | 1400 | 2160 | 1750 | 1440 | 2050 | 1690 | 1420 |

| Injection Speed | mm/s | 114 | 96 | 91 | ||||||

| Injection Stroke | MM | 215 | 220 | 250 | ||||||

| Plasticising Cap (ps) @ Max. Speed | GM/SEC | 16 | 25 | 35.7 | 26.2 | 30 | 37 | 31.5 | 32 | 49 |

| Screw speed | rpm | 0~260 | 0~180 | 0~180 | ||||||

| Clamping Unit | ||||||||||

| Clamping force | TONNES | 140 | 180 | 240 | ||||||

| Toggle Strock | mm | 420 | 470 | 540 | ||||||

| Space between tie bars | mm | 465 x 465 | 515 x 515 | 570 x 570 | ||||||

| Max. Mould Height | mm | 480 | 530 | 600 | ||||||

| Min. Mould Height | mm | 180 | 200 | 220 | ||||||

| Ejector Stroke | mm | 130 | 130 | 130 | ||||||

| Ejector Force | TONNES | 3.96 | 6.2 | 6.2 | ||||||

| Ejector Number | n | 5 | 8+1 | 9 | ||||||

| Others | ||||||||||

| Max. Pump Pressure | BAR | 150 | 150 | 150 | ||||||

| Pump Motor Power | KW | 15 | 18.5 | 22 | ||||||

| Heater Power | KW | 13 | 14.8 | 16.7 | ||||||

| Machine Dimensions (L x W x H) | m | 4.98 x 1.21 x 2.22 | 5.60 x 1.34 x 2.27 | 5.84 x 1.41 x 2.34 | ||||||

| Oil Tank Capacity | Liter | 240 | 320 | 360 | ||||||

| Machine Weight | Ton | 5.5 | 6.7 | 9 | ||||||

* Due to quality development and continuous improvements process, technical data may change without prior notice.