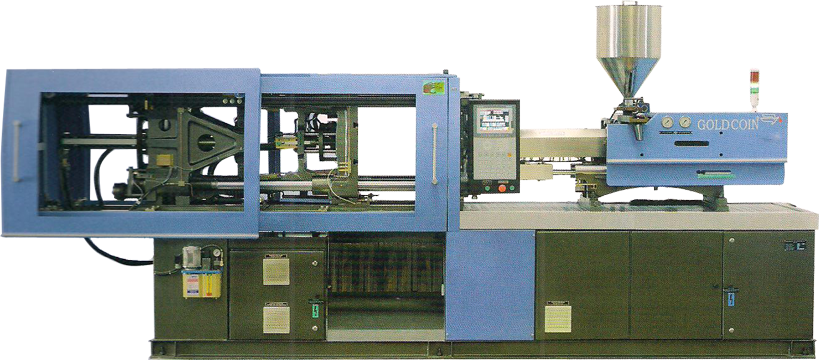

Single Color Thermoplastic Injection Molding

NP Series

Clamping Unit

- Integrated Casted Vertical Five Point Double Toggle System

- T-Slot - Drilling Taping for Mold Clamp

- Three Stage Mould Open/Close Speed

- Sensitive Low Pressure Mould Safety

- Linear Scale For Position Based Functions

- Motorized Mould Height Adjustment With Auto Tonnage Built up

- Guard Safety

- Hydraulic Ejector System (Linear Scale based - Multi Points - Multi Stroke)

- Centralized Auto Lubrication System ( Grease Based )

- Air Ejector System ( Both Halves )

- Core Pulling (Single Cylinder)

- Core Pulling Provision ( For Second Cylinder)

Injection Unit

- Twin Cylinder Balanced Injection Unit

- Five Stage Reduced Injection Pressure System

- Linear Scale For Position Based Functions

- Five Stage Reduced Injection Speed System

- Auto Reciprocating Injection Unit

- Suck Back System

- Heating Insulation Cover

- Injection Hold On System

- Radial Piston Hydro Motor

- Back Pressure Control (Manual)

Control

- Color Monitor

- Programmable Logical Controller

- Audio Visual Alarm

Hydraulic

- Energy Saving Variable Displacement Pump

- Power Saver Servo Motor Control

- Bi-Metal Screw Barrel

- Dynamic Barrier Screw

- Back Pressure Control (PLC Based)

- Water Battery

- Ejector On Fly

| SR.NO | DESCRIPTION | UNIT | NP 50/100 | NP 70/140 | NP 100/200 | NP 125/250 | NP 150/300 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | INJECTION UNIT | B | A | B | C | A | B | C | A | 8 | C | A | B | C | |||

| 1 | SCREW DIAMETER | MM | 30 | 35 | 37 | 40 | 37 | 40 | 43 | 40 | 45 | 48 | 45 | 50 | 55 | ||

| 2 | INJECTION PRESSURE | BAR | 1840 | 1930 | 1730 | 1480 | 1960 | 1680 | 1450 | 2010 | 1590 | 1400 | 2160 | 1750 | 1440 | ||

| 3 | SYSTEM PRESSURE | BAR | 150 | 150 | 150 | 150 | 150 | ||||||||||

| 4 | SCREW SI ROKE | MM | 125 | 125 | 165 | 215 | 220 | ||||||||||

| 5 | STROKE VOLUME | CC | 88 | 123 | 137 | 160 | 172 | 201 | 232 | 270 | 342 | 389 | 334 | 412 | 499 | ||

| 6 | SHOT WEIGHT (PS) | GMS | 86 | 110 | 123 | 145 | 154 | 181 | 209 | 243 | 308 | 350 | 301 | 371 | 449 | ||

| 7 | INJECTION RATE | GMS/SEC | 50 | 68 | 77 | 90 | 103 | 120 | 139 | 116 | 171 | 194 | 137 | 169 | 204 | ||

| 8 | INJECTION TIME | SECOND | 2.2 | 1.6 | 1.5 | 2.1 | 2.2 | ||||||||||

| 9 | PIASTICISING CAP. (PS) **MAX.SPEED |

GMS/SEC | 7.5 | 14 | 14 | 19.2 | 11.7 | 14 | 15.8 | 12.3 | 16 | 18 | 19.6 | 25 | 29.3 | ||

| 10 | L/D RATIO | 21 | 20.6 | 19.5 | 18 | 21.1 | 19.6 | 18.2 | 22.5 | 20 | 18.8 | 22.2 | 20 | 18.2 | |||

| 11 | SCREW REVOLUTION | RPM | 280 | 210 | 230 | 250 | 250 | ||||||||||

| 12 | HEATING CAPACITY | KW | 5.20 | 5.8 | 9.1 | 13 | 14.8 | ||||||||||

| 13 | NO. Of HEATING ZONE | NOS | 4 | 4 | 4 | 5 | 5 | ||||||||||

| 14 | NOZZLE CONTACT FORCE | TONNES | 2.5 | 3.2 | 3.2 | 4.6 | 6.5 | ||||||||||

| 15 | LOCATING RING DIAMETER | MM | 100 | 100 | 125 | 125 | 160 | ||||||||||

| B | LOCKING UNIT | ||||||||||||||||

| TYPE (INTEGRATED CAST) | VERTICAL | VERTICAL | VERTICAL | VERTICAL | VERTICAL | ||||||||||||

| 17 | CLAMPING FORCE | TONNES | 50 | 80 | 100 | 125 | 150 | ||||||||||

| 18 | MOULD OPENING STROKE | MM | 260 | 320 | 365 | 420 | 470 | ||||||||||

| 19 | MAX/MIN MOLD HEIGHT | MM | 320/120 | 380/150 | 450/160 | 480/180 | 530/200 | ||||||||||

| 20 | MAX. DAYLIGHT | MM | 580 | 700 | 815 | 820 | 950 | ||||||||||

| 21 | DIST. BETWEEN TIE BAR | MM | 310X310 | 365X365 | 410X410 | 465X465 | 515X515 | ||||||||||

| 22 | SIZE OF MOULD PLATEN | MM | 480X480 | 545X545 | 600X600 | 680X680 | 765X765 | ||||||||||

| 23 | EJECTOR FORCE | TONNES | 2.2 | 2.75 | 3.9 | 4 | 6.2 | ||||||||||

| 24 | EJECTOR STROKE | MM | 70 | 100 | 130 | 130 | 130 | ||||||||||

| 25 | NO. OF EJECTOR PIN | NOS | 4+1 | 5 | 4+1 | 4+1 | 8+1 | ||||||||||

| C | GENERAL DATA | ||||||||||||||||

| 26 | PUMP DRIVE | KW | 5.5 | 11 | 11 | 15 | 18.5 | ||||||||||

| 27 | TOTAL LOAD | KW | 12.70 | 16.8 | 20.1 | 28 | 33.3 | ||||||||||

| 28 | OIL TANK CAPACITY | LITRE | 135 | 185 | 230 | 240 | 320 | ||||||||||

| 29 | MACHINE DIM. LXWXH | MTR | 4.00X1.30X1.70 | 3.92X1.08X2.04 | 4.39X1.12X2.08 | 4.98X1.21X2.22 | 5.60X1.34X1.27 | ||||||||||

| 30 | MACHINE WEIGHT | TONNES | 4 | 4.5 | 5 | 5.5 | 6.7 | ||||||||||

| SR.NO. | DESCRIPTION | UNIT | NP 200/400 | NP 250/500 | NP 350/700 | NP 450/900 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | INJECTION UNIT | A | B | C | A | B | C | A | B | C | A | B | C | |

| 1 | SCREW DIAMETER | MM | 50 | 55 | 60 | 60 | 65 | 70 | 65 | 70 | 75 | 75 | 80 | 84 |

| 2 | INJECTION PRESSURE | BAR | 2050 | 1690 | 1420 | 2100 | 1800 | 1550 | 2050 | 1800 | 1550 | 1770 | 1560 | 1410 |

| 3 | SYSTEM PRESSURE | BAR | 150 | 150 | 150 | 150 | ||||||||

| 4 | SCREW STROKE + SB | MM | 235+15 | 240+20 | 310+20 | 370+20 | ||||||||

| 5 | STROKE VOLUME | CC | 490 | 593 | 707 | 727 | 853 | 989 | 1094 | 1269 | 1457 | 1722 | 1959 | 2160 |

| 6 | SHOT WEIGHT(PS) | GMS | 441 | 534 | 636 | 662 | 776 | 900 | 995 | 1150 | 1325 | 1567 | 1786 | 1966 |

| 7 | INJECTION RATE | GMS/SEC | 176 | 213 | 254 | 180 | 214 | 248 | 229 | 265 | 303 | 412 | 470 | 517 |

| 8 | INJECTION TIME | SECOND | 2.5 | 2.9 | 3.5 | 3.8 | ||||||||

| 9 | PLASTICISING CAP.(PS) **MAX.SPEED |

GMS/SEC | 25 | 28 | 36 | 35 | 40 | 48 | 40 | 45 | 55 | 45 | 50 | 58 |

| 10 | L/D RATIO | 22.5 | 20:01 | 18 | 21 | 20:01 | 18 | 22 | 20 | 19 | 21 | 20:01 | 19 | |

| 11 | SCREW REVOLUTION | RPM | 180 | 180 | 180 | 160 | ||||||||

| 12 | HEATING CAPACITY | KW | 16.7 | 21 | 25 | 23.65 | ||||||||

| 13 | NO. OF HEATING ZONE | 5 | 6 | 7 | 9 | |||||||||

| 14 | NOZZLE CONTACT FORCE | TONNES | 7 | 7 | 10 | 10 | ||||||||

| 15 | LOCATING RING DIAMETER | MM | 160 | 160 | 160 | 200 | ||||||||

| B | LOCKING UNIT | |||||||||||||

| 16 | TYPE( lNTEGRATED CAST) | VERTICAL | VERTICAL | VERTICAL | VERTICAL | |||||||||

| 17 | CLAMPING FORCE | TONNES | 200 | 250 | 350 | 450 | ||||||||

| 18 | MOLD OPENING STROKE | MM | 540 | 600 | 700 | 825 | ||||||||

| 19 | MAX/MIN MOLD HEIGHT | MM | 600/220 | 660/250 | 750/250 | 820/300 | ||||||||

| 20 | MAX. DAYLIGHT | MM | 1140 | 1260 | 1450 | 1570 | ||||||||

| 21 | DIST.BETWEEN TIE BAR | MM | 570 X 570 | 660 X 660 | 725 X 705 | 800 X 800 | ||||||||

| 22 | SIZE OF MOLD PLATEN | MM | 840 X 840 | 960 X 960 | 1040 X 1020 | 1110 X 1148 | ||||||||

| 23 | EJECTOR FORCE | TONNES | 6.2 | 8 | 13 | 14 | ||||||||

| 24 | EJECTOR STROKE | MM | 130 | 160 | 160 | 200 | ||||||||

| 25 | NO. OF EJECTOR PIN | NOS | 9 | 13 | 15 | 13 | ||||||||

| C | GENERAL DATA | |||||||||||||

| 25 | PUMP DRIVE | KW | 22 | 30 | 37 | 45 | ||||||||

| 26 | TOTAL LOAD | KW | 36.7 | 51 | 62 | 68.65 | ||||||||

| 27 | OIL TANK CAPACITY | LITRE | 360 | 550 | 650 | 700 | ||||||||

| 28 | MACHINE DIM. L X W X H | MTR | 6.00 X 1.14 X 2.34 | 6.8 X 1.9 X 2.42 | 7.23 X 1.87 X 2.57 | 8.00 X 1.92 X 2.71 | ||||||||

| 29 | MACHINE WEIGHT | TONNES | 9 | 11 | 15 | 20 | ||||||||